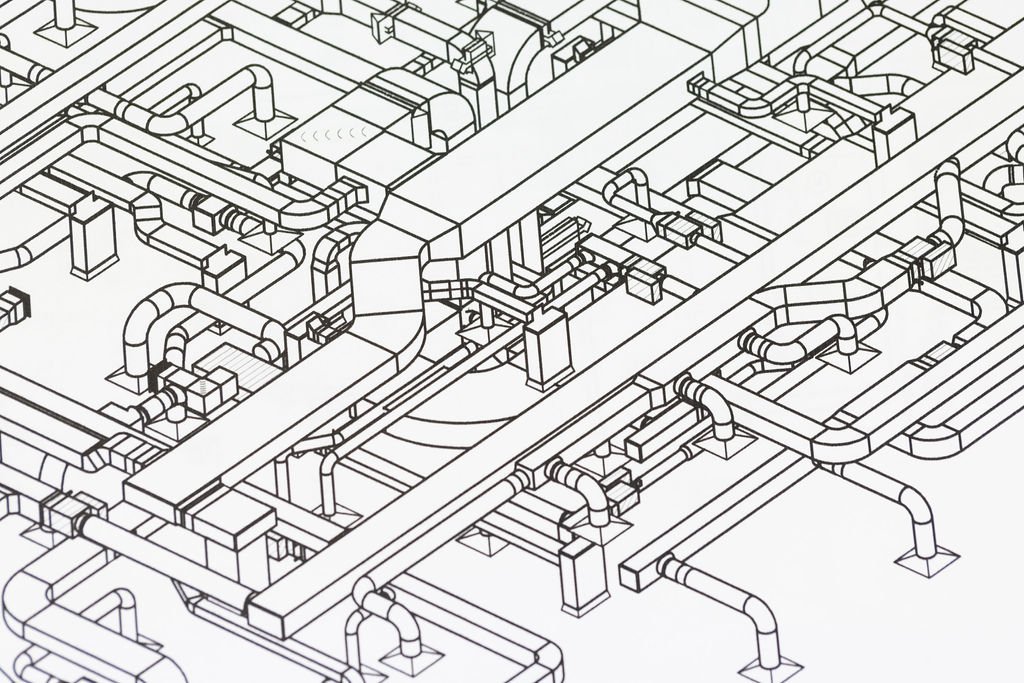

HVAC

Our team of skilled professionals has the experience and knowledge to understand various HVAC systems in commercial buildings

We ensure that the systems are properly installed, maintained and repaired for optimal performance and energy efficiency. We have the capability to handle all your commercial HVAC service needs, from the installation of new systems to ongoing maintenance and repairs.

Luckinbill aims to surpass your HVAC service expectations for your facilities and commercial properties. We pride ourselves on responsiveness, flexibility and excellent customer service. Our high-performance standards ensure you save money on equipment repair and replacement costs and prevent lost revenue. Our HVAC team will work to find timely and economical solutions to any commercial building or industrial HVAC challenge, all backed by our full one-year warranty.

Our specialists are available 24/7/365, giving you assurance as an owner or decision maker, that Luckinbill will be there for you day or night.

Oklahoma’s HVAC Company

Luckinbill offers a variety of industrial and commercial HVAC services, including:

24/7 emergency repair services

Compliance with local codes and regulations

HVAC system retrofits

New HVAC system installation

Preventative maintenance programs

Upgrades and retrofits

Energy Recovery Units

Ductwork, stainless steel, galvanized, black iron and plastic

Commercial chillers and boilers

Make-up air units, supply fans

Stainless steel kitchen hoods and grease ducts

Fan coil units

Air handling units

Exhaust fans

CRAC Units/Liebert Systems

Clean room equipment

Architectural louvers and dampers

Multi-one systems

Planned Maintenance vs. Reactive Maintenance

At Luckinbill, we specialize in creating customized planned maintenance programs for HVAC equipment, also known as preventive maintenance. Our program optimizes your equipment's performance, delivering acceptable thermal comfort, increased energy efficiency and improved indoor air quality. With our program in place, our clients experience higher employee productivity due to the greater comfort provided. Our maintenance program can help you expect greater creature comfort and productivity, reduce equipment downtime, increase equipment lifespan and reduce repair costs.

In contrast, reactive maintenance may seem like a cost-effective option upfront, but it can increase ownership costs over time. The longer your equipment goes without regular maintenance, the less efficient it becomes and an air conditioner can lose up to 15% of its efficiency within three months of its last service. This reduction in efficiency leads to a decrease in employee comfort and productivity, which only adds to the increased cost of operation. Over time, the equipment will work harder, making it more susceptible to component failure. The continued cycle of equipment failure and long run times will significantly decrease the lifespan of your equipment. Repairs to deferred maintenance equipment will often cost more because the deferred maintenance that caused the failure in the first place will now have to be resolved along with replacement of the failed components. Ultimately, you will end up paying for the maintenance without reaping the benefits of a Planned Maintenance program.

Investing in a planned maintenance program with Luckinbill can provide you with more benefits and cost savings over time compared to reactive maintenance. Our program ensures that your HVAC equipment operates at peak performance, reducing downtime, increasing equipment lifespan and optimizing employee comfort and productivity.

A solid maintenance plan is key to avoiding unnecessary and costly breakdowns:

Improper refrigerant charge can lower system efficiency by 20%.

Proper sealing and insulation can reduce cooling energy use by 10–15%.

A customized preventive maintenance plan could save 30% or more on your building or facilities' utility bills.

Cleaning and/or adjusting of belts, filters and VFD’s can improve efficiency by another 5–10%.

Regardless of how well-tuned it is, a system will not operate efficiently if the duct system is in poor condition. Proper sealing and insulation can reduce cooling energy use by 10–15%.

A typical compressor failure can cost thousands of dollars to repair, but changing it routinely can help save you money down the line.

Servicing Oklahoma and Surrounding States

Building You a Better Tomorrow.

Plan Your Next Project with Luckinbill!

Emergency Services Available 24/7!